Injin Ciko Vial a cikin Magunguna

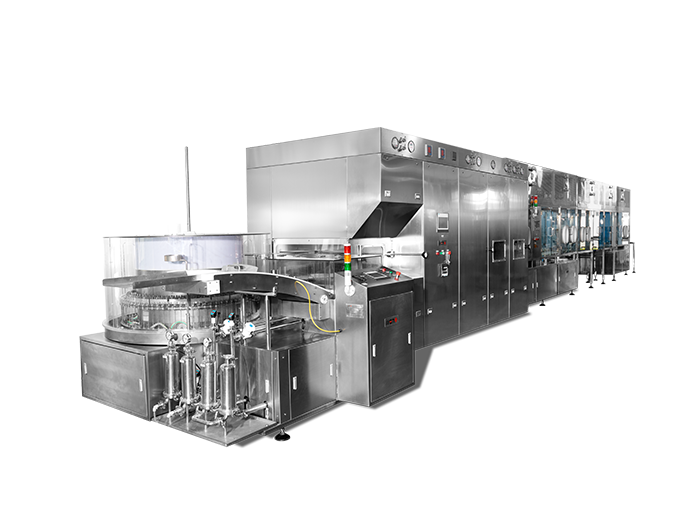

TheInjin cika vialana amfani da shi sosai a cikin masana'antar harhada magunguna don cika vials tare da kayan aikin magani. Waɗannan injunan ɗorewa an ƙirƙira su don yin daidaitaccen aiki na cikewar vial. Injin cika vial suma sun ƙunshi kawunan masu cikawa da yawa waɗanda ke taimaka musu samun ƙimar cikawa mai girma da haɓaka yawan aiki don biyan buƙatun masana'antar harhada magunguna. Akwai bambance-bambancen injunan cika vial da yawa waɗanda suka dace da aikace-aikace daban-daban a cikin masana'antar harhada magunguna.

Ƙa'idar Aiki na Vial Filling Machine

TheInjin cika vialya ƙunshi mai jigilar SS slat don ƙaƙƙarfan motsi na vials akan injin cikawa. Daga bel ɗin isar da saƙo, sai a tura da bakararre na fanko zuwa wurin da ake cikawa, inda aka cika abubuwan da ake buƙata na magunguna da yawa. Tashoshin cika sun ƙunshi kawuna da yawa ko nozzles waɗanda ke ba da damar cika vial da sauri ba tare da sharar gida ba. Adadin shugabannin cikawa daga 2 zuwa 20 ana iya keɓance su gwargwadon buƙatun masana'anta. Filayen suna cika daidai da shugabannin cikawa, bayan haka za'a canza filayen zuwa tashar ta gaba akan layin cikawa. Injin yana kiyaye daidaiton haifuwa a duk lokacin ayyukan cikawa. A tasha ta gaba, ana sanya masu tsayawa a kan kan kwalayen. Wannan yana tabbatar da cewa an kiyaye haifuwar haifuwa da amincin abubuwan abubuwan. A lokacin aikin cikawa, yana da mahimmanci don tabbatar da cewa kayan aikin magunguna da kwalayen ba su da gurɓata. Duk wani hargitsi tare da abubuwan sinadaran na iya haifar da ƙin yarda da dukkan nau'in vial ɗin. Ana rufe masu tsayawa a rufe a rufe kafin a je wurin yin lakabin.

Nau'in Injin Ciko Vial

Yana da hankali don fahimtar nau'ikan injunan cika vial daban-daban da ke akwai da ƙira, aikace-aikacensu da tsarin aiki. A ƙasa muna kwatanta nau'ikan injunan cika vial daban-daban tare da bayanan su:

Injin Ciko Vial

Thena'urar cika kwalbar magungunaAna amfani da shi a cikin masana'antar harhada magunguna kuma ana kiran injin ɗin injectable vial ɗin cikawa kuma ya haɗa da filler ɗin vial da masu dakatar da roba. Wadannan injunan cikawa ta atomatik suna tabbatar da daidaito a cikin ƙara, rage asarar samfur, kuma sun zo tare da ginanniyar tsarin kula da inganci don bincika ƙarar lokaci na vials. Ana amfani da injunan cika kwalbar magani a cikin aikace-aikacen bakararre da marassa haifuwa.

Injin Cika Liquid Vial

TheInjin cika ruwa vialya ƙunshi babban inji, unscrambler, conveyor, stopper ciyar tasa da scrambler. Belin mai jigilar kaya yana jujjuya filaye zuwa tashar cikawa, inda abin da ke cikin ruwa ke cika cikin injin. Injin cika ruwa na Vial suna cika ruwa ko ruwaye na viscosities daban-daban a cikin vials. Ana amfani da waɗannan injunan ko'ina a cikin masana'antar harhada magunguna don tabbatar da cikar madaidaicin vials. Injin cika ruwa na vials yana aiki akan bututun ruwa da ka'idar juzu'i, wanda ke ba da ingantaccen aikin cikawa.

Vial Powder Filling Machine

TheVial foda cika injiya ƙunshi ayyukan wankewa, bakarawa, cikawa, hatimi da ayyukan lakabi. Duk kayan aikin suna daidaitawa akan layin cikawa don tabbatar da ci gaba da samar da vials don masana'antar magunguna. Injin cika foda ta atomatik yana da mahimmanci a cikin masana'antar harhada magunguna saboda hakan yana taimakawa cika granules ko foda a cikin vials.

Injin Cika Liquid Mai allura

Layin cika ruwa ko injin yana aiki ƙarƙashin babban matsin lamba. Sabili da haka, ana iya kuma ƙira shi azaman cika matsi na ruwa. A cikin wannan tsari, allurar ruwa yana gudana a cikin kwalabe na ajiya dangane da nauyin nauyi lokacin da matsa lamba a cikin tafki ruwa ya zama daidai da karfin iska a cikin kwalban.

Thelayukan cika ruwa mai allurasuna da sauƙin aiki kuma suna cika madaidaicin adadin ruwa cikin kwalabe, kwantena ko galan. Tsarin cikawa da aka gina a cikin injin yana ba shi damar daidaita ƙimar cikawa da adadin kowane girman kwalban ko akwati ba tare da maye gurbin kowane kayan aiki ba. Wadannan inji suna sanye take da na'urori masu auna firikwensin da za su iya dakatar da aikin ta atomatik ba tare da wani kwalban a kan bel ba.

Lokacin aikawa: Nuwamba-20-2024